North America Is Dominating SCADA Market

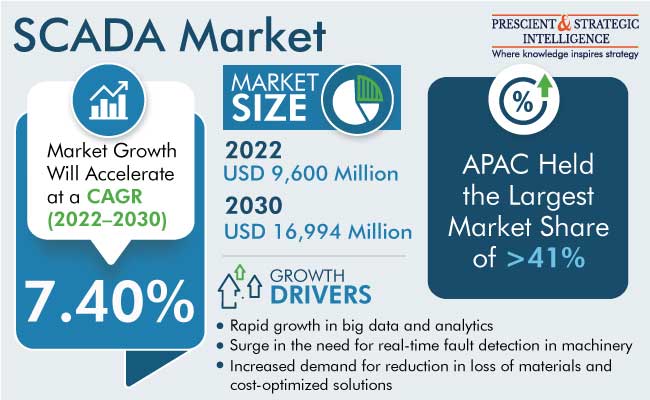

The total value of the global SCADA market was USD 9,600 million in 2022, and it will rise at a growth rate of above 7.4% shortly, reaching USD 16,994 million by 2030, according to P&S Intelligence.

This growth can be credited to the high acceptance of Industry 4.0 solutions utilizing SCADA devices, the rising usage of software platforms including artificial intelligence and the Internet of Things, the growing requirement for industrial mobility solutions for better procedure management, and the growing advancements in wireless sensor networks (WSNs).

Artificial intelligence and the Internet of Things have enhanced the processes of numerous sectors. On the basis of different world statistics, the count of devices linked to IoT networks is quickly growing.

Through the usage of SCADA arrangements, the IoT is altering manufacturing facilities by joining a huge network of smart systems. IoT and AI-based arrangements allow industries to control and screen their developments and applications, precisely forecast machine failure, and attain quicker response times, thus growing effectiveness and reducing operational prices.

Furthermore, by utilizing IoT and AI, information is gathered, analyzed, and utilized for rising predictive models, which can help in making work well-organized and lead to augmented incomes for a company. In order to modernize plant processes, IoT and AI-based SCADA platforms streamline data transmission and study.

The surge in the rise of Industry 4.0 for both process industries and manufacturing industries quickens industry development. They utilize such facilities as part of their digitalization strategies.

Because of their high level of technology adoption, industries are witnessing a high requirement to update the present SCADA system. Therefore, the need for these systems has been growing, mainly because of the digitization of manufacturing processes via the usage of sensors and data devices.

In the coming few years, the hardware category is projected to advance at the highest development rate, of approximately 7.8%. This can be credited to the high requirement for components such as RTU, HMI, and PLC in industrial processes and mechanization solutions to attain the targets of scalability, efficiency, and growth in the manufacturing sector.

Furthermore, progressive hardware advances the performance of systems, accountable for process mechanization, and delivers valued data. Therefore, the industry’s key players employed technologies for the growth of HMI and progressive PLCs, which can work with diverse SCADA solutions.

In recent years, North America held the major revenue share in the worldwide SCADA market. This is mainly because of the steady energy management of SCADA, huge expenditure on technologies, the increasing industrial sector, and the rising acceptance of automation technology.

Hence, the high acceptance of Industry 4.0 solutions utilizing SCADA devices, the rising usage of software platforms including artificial intelligence and the Internet of Things, and the growing requirement for industrial mobility solutions for better procedure management are the major factors propelling the SCADA market.

Read More: https://www.psmarketresearch.com/market-analysis/scada-market

The total value of the global SCADA market was USD 9,600 million in 2022, and it will rise at a growth rate of above 7.4% shortly, reaching USD 16,994 million by 2030, according to P&S Intelligence.

This growth can be credited to the high acceptance of Industry 4.0 solutions utilizing SCADA devices, the rising usage of software platforms including artificial intelligence and the Internet of Things, the growing requirement for industrial mobility solutions for better procedure management, and the growing advancements in wireless sensor networks (WSNs).

Artificial intelligence and the Internet of Things have enhanced the processes of numerous sectors. On the basis of different world statistics, the count of devices linked to IoT networks is quickly growing.

Through the usage of SCADA arrangements, the IoT is altering manufacturing facilities by joining a huge network of smart systems. IoT and AI-based arrangements allow industries to control and screen their developments and applications, precisely forecast machine failure, and attain quicker response times, thus growing effectiveness and reducing operational prices.

Furthermore, by utilizing IoT and AI, information is gathered, analyzed, and utilized for rising predictive models, which can help in making work well-organized and lead to augmented incomes for a company. In order to modernize plant processes, IoT and AI-based SCADA platforms streamline data transmission and study.

The surge in the rise of Industry 4.0 for both process industries and manufacturing industries quickens industry development. They utilize such facilities as part of their digitalization strategies.

Because of their high level of technology adoption, industries are witnessing a high requirement to update the present SCADA system. Therefore, the need for these systems has been growing, mainly because of the digitization of manufacturing processes via the usage of sensors and data devices.

In the coming few years, the hardware category is projected to advance at the highest development rate, of approximately 7.8%. This can be credited to the high requirement for components such as RTU, HMI, and PLC in industrial processes and mechanization solutions to attain the targets of scalability, efficiency, and growth in the manufacturing sector.

Furthermore, progressive hardware advances the performance of systems, accountable for process mechanization, and delivers valued data. Therefore, the industry’s key players employed technologies for the growth of HMI and progressive PLCs, which can work with diverse SCADA solutions.

In recent years, North America held the major revenue share in the worldwide SCADA market. This is mainly because of the steady energy management of SCADA, huge expenditure on technologies, the increasing industrial sector, and the rising acceptance of automation technology.

Hence, the high acceptance of Industry 4.0 solutions utilizing SCADA devices, the rising usage of software platforms including artificial intelligence and the Internet of Things, and the growing requirement for industrial mobility solutions for better procedure management are the major factors propelling the SCADA market.

Read More: https://www.psmarketresearch.com/market-analysis/scada-market

North America Is Dominating SCADA Market

The total value of the global SCADA market was USD 9,600 million in 2022, and it will rise at a growth rate of above 7.4% shortly, reaching USD 16,994 million by 2030, according to P&S Intelligence.

This growth can be credited to the high acceptance of Industry 4.0 solutions utilizing SCADA devices, the rising usage of software platforms including artificial intelligence and the Internet of Things, the growing requirement for industrial mobility solutions for better procedure management, and the growing advancements in wireless sensor networks (WSNs).

Artificial intelligence and the Internet of Things have enhanced the processes of numerous sectors. On the basis of different world statistics, the count of devices linked to IoT networks is quickly growing.

Through the usage of SCADA arrangements, the IoT is altering manufacturing facilities by joining a huge network of smart systems. IoT and AI-based arrangements allow industries to control and screen their developments and applications, precisely forecast machine failure, and attain quicker response times, thus growing effectiveness and reducing operational prices.

Furthermore, by utilizing IoT and AI, information is gathered, analyzed, and utilized for rising predictive models, which can help in making work well-organized and lead to augmented incomes for a company. In order to modernize plant processes, IoT and AI-based SCADA platforms streamline data transmission and study.

The surge in the rise of Industry 4.0 for both process industries and manufacturing industries quickens industry development. They utilize such facilities as part of their digitalization strategies.

Because of their high level of technology adoption, industries are witnessing a high requirement to update the present SCADA system. Therefore, the need for these systems has been growing, mainly because of the digitization of manufacturing processes via the usage of sensors and data devices.

In the coming few years, the hardware category is projected to advance at the highest development rate, of approximately 7.8%. This can be credited to the high requirement for components such as RTU, HMI, and PLC in industrial processes and mechanization solutions to attain the targets of scalability, efficiency, and growth in the manufacturing sector.

Furthermore, progressive hardware advances the performance of systems, accountable for process mechanization, and delivers valued data. Therefore, the industry’s key players employed technologies for the growth of HMI and progressive PLCs, which can work with diverse SCADA solutions.

In recent years, North America held the major revenue share in the worldwide SCADA market. This is mainly because of the steady energy management of SCADA, huge expenditure on technologies, the increasing industrial sector, and the rising acceptance of automation technology.

Hence, the high acceptance of Industry 4.0 solutions utilizing SCADA devices, the rising usage of software platforms including artificial intelligence and the Internet of Things, and the growing requirement for industrial mobility solutions for better procedure management are the major factors propelling the SCADA market.

Read More: https://www.psmarketresearch.com/market-analysis/scada-market

·7KB Ansichten

·0 Vorschau