Encoder Market IS Dominated by the North American Region

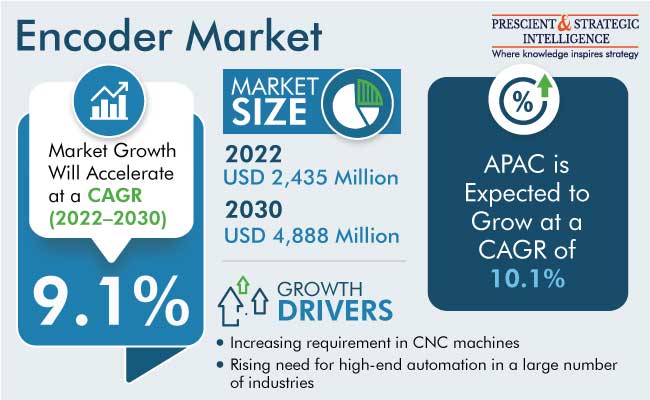

As per a research report by P&S Intelligence, the total size of the encoder market was USD 2,435 million in 2022, and it will propel at a rate of 9.10% by the end of this decade, to reach USD 4,888 million by 2030.

Rotary encoders had a major share, of revenue, of approximately 58%, in the past. This has a lot to do with the increasing industrial automation across several industries, such as packaging, aerospace, healthcare, electronics, and automotive, for measuring angular speed, position, and rotation of moving parts in a variety of applications.

Automation in more than a few industries will power the requirement for robotics, which, in line, will increase the requirement for rotary angle sensors. Furthermore, with the progression of high-resolution systems, these devices have varied uses in industrial and commercial sectors.

The absolute category will grow the fastest in the years to come, on account of its use in a wide variety of applications requiring control or monitoring, or both.

It comprises of diagnostic imaging and surgical robotics, which help in measuring the precise position of the product with the help of unique digital codes and offer them unique position values instantly as they are put on by scanning the location of the coded element.

Also, it offers the data rather than an output of pulses, but an output that is a precise value in a binary format.

Optical sensing encoders have the largest share in the industry. This is due to the fact that they use light shone through a coded disk supporting in tracking the movement of the shaft.

Likewise, these systems have numerous advantages for example better angular accuracy, better reliability, high resolution, operating in extreme environments, large hollow shaft encoders, and being light in weight.

Furthermore, the requirement for magnetic encoder technology is also increasing significantly, and advancing rapidly than optical sensing technology. This is due to the fact that magnetic scales generated for dissimilar lengths, numbers, and designs of tracks, and can also be put to use for numerous applications against harsh environments and small sizes.

North America dominates the encoder market with USD 1,515 million. This is because of the increasing manufacturing of auto parts, the increasing car count, the growing demand for consumer electronics, and the expanding R&D activities in advanced technologies.

Furthermore, a numerous key players are present in the region, thus making it easier for users to obtain these semiconductor components.

It is because of the increasing requirement for high-end automation in numerous industries, the demand for encoders, all over the world will grow at pace in the future.

Read More:

https://www.psmarketresearch.com/market-analysis/encoder-market-reportEncoder Market IS Dominated by the North American Region

As per a research report by P&S Intelligence, the total size of the encoder market was USD 2,435 million in 2022, and it will propel at a rate of 9.10% by the end of this decade, to reach USD 4,888 million by 2030.

Rotary encoders had a major share, of revenue, of approximately 58%, in the past. This has a lot to do with the increasing industrial automation across several industries, such as packaging, aerospace, healthcare, electronics, and automotive, for measuring angular speed, position, and rotation of moving parts in a variety of applications.

Automation in more than a few industries will power the requirement for robotics, which, in line, will increase the requirement for rotary angle sensors. Furthermore, with the progression of high-resolution systems, these devices have varied uses in industrial and commercial sectors.

The absolute category will grow the fastest in the years to come, on account of its use in a wide variety of applications requiring control or monitoring, or both.

It comprises of diagnostic imaging and surgical robotics, which help in measuring the precise position of the product with the help of unique digital codes and offer them unique position values instantly as they are put on by scanning the location of the coded element.

Also, it offers the data rather than an output of pulses, but an output that is a precise value in a binary format.

Optical sensing encoders have the largest share in the industry. This is due to the fact that they use light shone through a coded disk supporting in tracking the movement of the shaft.

Likewise, these systems have numerous advantages for example better angular accuracy, better reliability, high resolution, operating in extreme environments, large hollow shaft encoders, and being light in weight.

Furthermore, the requirement for magnetic encoder technology is also increasing significantly, and advancing rapidly than optical sensing technology. This is due to the fact that magnetic scales generated for dissimilar lengths, numbers, and designs of tracks, and can also be put to use for numerous applications against harsh environments and small sizes.

North America dominates the encoder market with USD 1,515 million. This is because of the increasing manufacturing of auto parts, the increasing car count, the growing demand for consumer electronics, and the expanding R&D activities in advanced technologies.

Furthermore, a numerous key players are present in the region, thus making it easier for users to obtain these semiconductor components.

It is because of the increasing requirement for high-end automation in numerous industries, the demand for encoders, all over the world will grow at pace in the future.

Read More: https://www.psmarketresearch.com/market-analysis/encoder-market-report

·6كيلو بايت مشاهدة

·0 معاينة